Projects

Grace Industries has been awarded 19 contracts at the Rockaway Boardwalk project, spread out over five phases. The new boardwalk design will raise it three feet higher than the 100-year storm elevation, and meeting the H-20 loading capacity. H-20 is the bridge design criteria established by the American Association of State Highway Transportation Officials, which specifies truck axle loading of 32,000 pounds, or wheel loading of 16,000 pounds. Each contract phase includes:

- Site preparation, salvage and removals – salvage existing materials, including metal railings, signage, World’s Fair benches and wood ramps. Remaining wood boardwalk, concrete piles, pile caps and deck are removed and disposed. Following the demolition of the existing structure, excavations are back-filled and the site is re-graded.

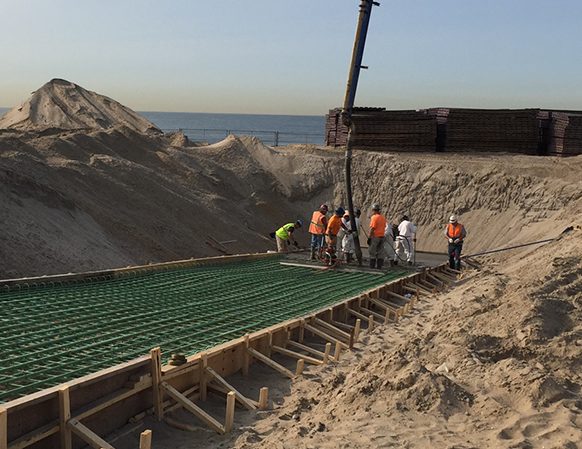

- Pile driving, sand retaining walls and pile caps – steel H piles are driven along with steel pipe piles. Precast concrete sand walls are set between the H piles and grouted in place. Precast pile caps are set onto the steel pipe piles, and a reinforced concrete plug is poured to connect the pile cap to the pile. Precast planks are set on the beach side to create pedestrian ramps from the boardwalk to the beach. Utility relocation, generally water main, is provided as required. All grades and alignment are maintained to ensure that the new the boardwalk meets the remaining existing sections.

- Site work and cast in place concrete – form and pour all ramps and stairs on the land side from new boardwalk to street level, as well as new sidewalks and concrete curbs. In Phases three and five, Grace’s value engineering switched cast-in-place ramps for precast planks, enabling us to work more efficiently in the winter months. Site grading and re-establishment of any dunes disturbed during construction is performed. Challenges overcome during this stage of work include exposed aggregate stairs and blue glass ramps.

- RPL decking – furnish and install RPL (recycled plastic lumber) decking on concrete ramp and stair structures to create a traditional wooden boardwalk aesthetic. RPL fascia is installed along the outside of ramps and stairs. Wood stairs and ramps are built on the beach side of the boardwalk. Furnish and install new World’s Fair benches and custom seats crafted of sourced reclaimed wood from the original boardwalk.

- Signage – furnish and install all new boardwalk and lifeguard signs for all phases.